Reinventing concrete

with a more responsible cement.

with a more responsible cement.

Clayson

Ecomineral inc.

We are committed to reducingCO2 emissions from the concrete industry. We achieve this through the use of calcined clay cement, a sustainable alternative that significantly reduces carbon emissions during production.

Net savings of

0.8 tonnes

of CO2 per tonne

of Clayson calcined clay

of Clayson calcined clay

Clayson clay replaces

30 at 50 %

polluting Portland cement in concrete production

Concrete produced from Clayson clay contains

40% less CO2

compared to Portland cement production

With one of the world’s largest clay deposits, Clayson aims to become the first large-scale producer of calcined pozzolanic clay to meet the need for greener concrete in the construction industry.

Calcined clay cement

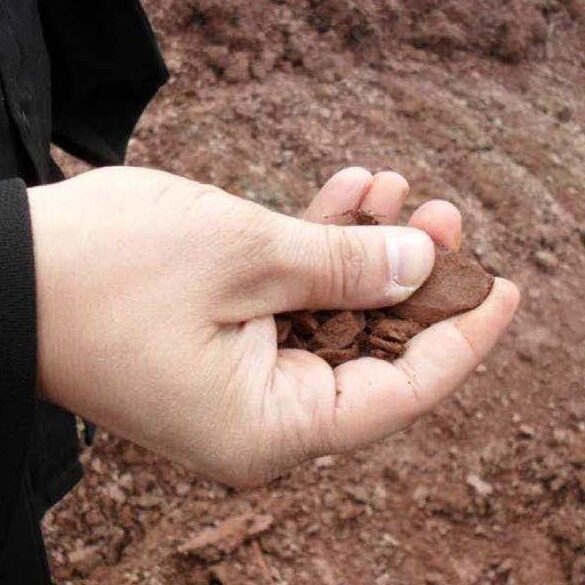

Calcined clay is a material obtained by heating natural clay, transformed to become an effective binder and partial replacement for cement. Its production only emits water unlike conventional cement. Used in concrete, it reducesCO2 emissions while delivering performance comparable to Portland cement.

News

Press release

Clayson Ecomineral obtains ministerial authorization for impact exploration work

Clayson Ecomineral is pleased to announce that it has received authorization to proceed with diamond drilling on its St-Damase deposit in the Matapedia RCM, in accordance with section 69 of the Mining Act (RLRQ, chapter M-13.1).

October 17, 2024

Sustainable development

Sustainable development is one of our core concerns, and plays a key role in all our activities.