The Calcined Clay Cement (CCC)

Calcined clay cement is a cost-effective ecological alternative that reducesCO2 emissions by up to 40% while delivering performance comparable to Portland cement.

What is calcined clay cement (CCC)?

Calcined clay is widely recognized as a sustainable substitute for cement clinker in cementing materials. It typically replaces 25 to 40% of the Portland cement in a concrete formulation.

Calcined clay cement, a low-carbon alternative to Portland cement, stands out for its significant environmental impact. It can slash CO2 emissions by up to 40%, making it a compelling choice for those concerned about climate change. Calcined clay cement has not only proven to be a reliable substitute for Portland cement but also a cost-effective one. It performs on par with Portland cement while being 25% cheaper to produce, thanks to energy and material savings.

Calcined clay cement (CCC) costs 25% less to produce while offering comparable performance.

In addition, it offers adequate mechanical qualities (e.g., durability), making it appropriate for various structural applications, including pavements, highways, residential and commercial buildings, and other infrastructure.

The production worldwide is rapidly increasing because many players in the industry are starting or constructing production facilities. Most of those new plants are located south of Europe, Africa, and the United States. Many factories have been operated in India, China, and Brazil for several years. Despite these significant interests, before Clayson’s discovery, no deposit was identified as satisfactory for starting production in the northeast of the US and Canada.

CLAYSON deposit is the best North American solution for CCC production.

Clayson deposit contains a large portion of kaolinite, showing excellent properties as a concrete binder. It can effectively replace around 20 to 40% of the actual Portland cement in concrete, thereby reducing the carbon footprint of concrete production and improving its properties.

The Clayson deposit, conveniently located near the surface with just 1 meter of overburden, requires no blasting. Its straightforward surface quarry exploitation process adds to its appeal, providing stakeholders with a sense of reassurance about the simplicity of the process.

The Clayson deposit stands out with its exceptional homogeneity, instilling confidence in stakeholders about the consistent quality of the resource. It is one of the largest clay deposits in the world (over 1 billion tons). Quebec province is well known for its low-cost hydroelectricity access. The Clayson CCC production would have a close to zero CO2 impact.

The Clayson deposit is an exceptional resource for reducing the carbon footprint of traditional concrete, with simple operation and near-zero C02 impact.

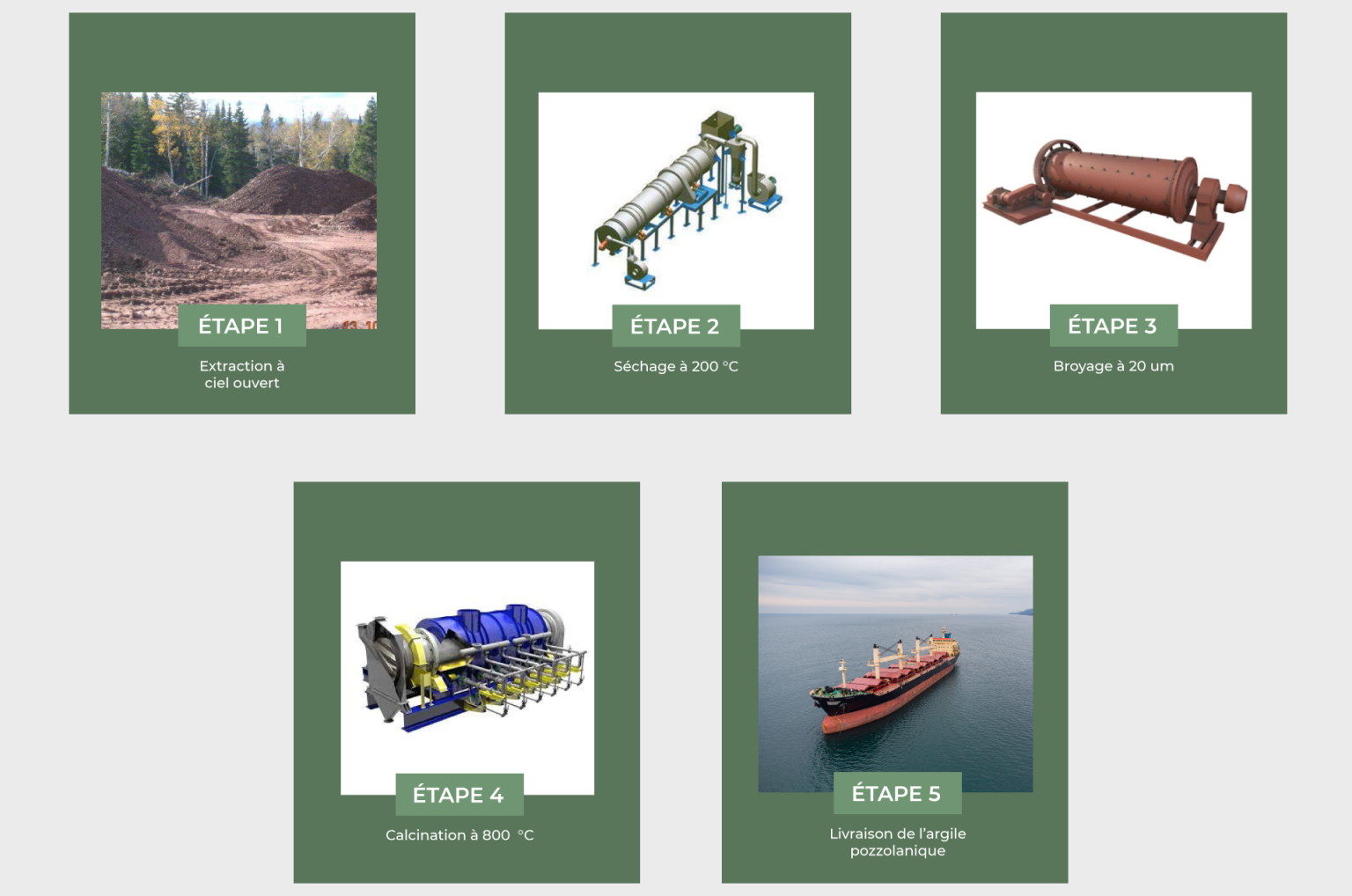

The process

The process

A strategic location close to river and rail transportation routes to supply northeastern Canada and the United States.

The Clayson deposit in an ideal location

The deposit has an ideal location for north-east Canada and USA supply

The property is located near the St Lawrence River, approximately 30 Kilometers from Matane in the Province of Quebec, Canada.

Matane has a deep-water port open yearly. The CN Rail line deserves Matane.